VRF HVAC systems – Service, Maintenance and Repair. St George Utah

The Engineering Mindset has produced a clear, practical explanation of how Variable Refrigerant Flow (VRF) systems work. Drawing on that explanation and expanding it for local commercial needs, EMCO Utah presents a comprehensive guide to VRF basics, how these systems provide simultaneous heating and cooling, why they are an excellent choice for buildings with varied thermal demands, and what servicing and repair in St. George, Utah looks like for property managers and building owners.

Why VRF? The Case for Variable Refrigerant Flow Systems

VRF—short for Variable Refrigerant Flow—refers to a class of advanced HVAC systems that vary the flow of refrigerant to match the exact heating and cooling demand in different indoor spaces. Rather than relying on a single on/off outdoor unit serving an entire building, VRF systems modulate refrigerant delivery and use multiple indoor terminal units. This flexibility brings several advantages for commercial properties in St. George:

- Precision temperature control for differing internal loads (conference rooms, server closets, guest rooms).

- Energy savings through inverter-driven compressors and matched expansion control.

- Space savings and reduced structural impact compared with multiple packaged rooftop units or separate hydronic systems.

- Ability to recover heat—moving thermal energy from parts of a building where it’s unwanted to where it’s needed—improving overall system efficiency.

EMCO Utah recommends VRF systems for hotels, office buildings, retail stores, clinics, and education facilities in St. George, where individual zones frequently require different setpoints and where both summer cooling and winter heating are important.

VRF System Components: What EMCO Utah Technicians Look At

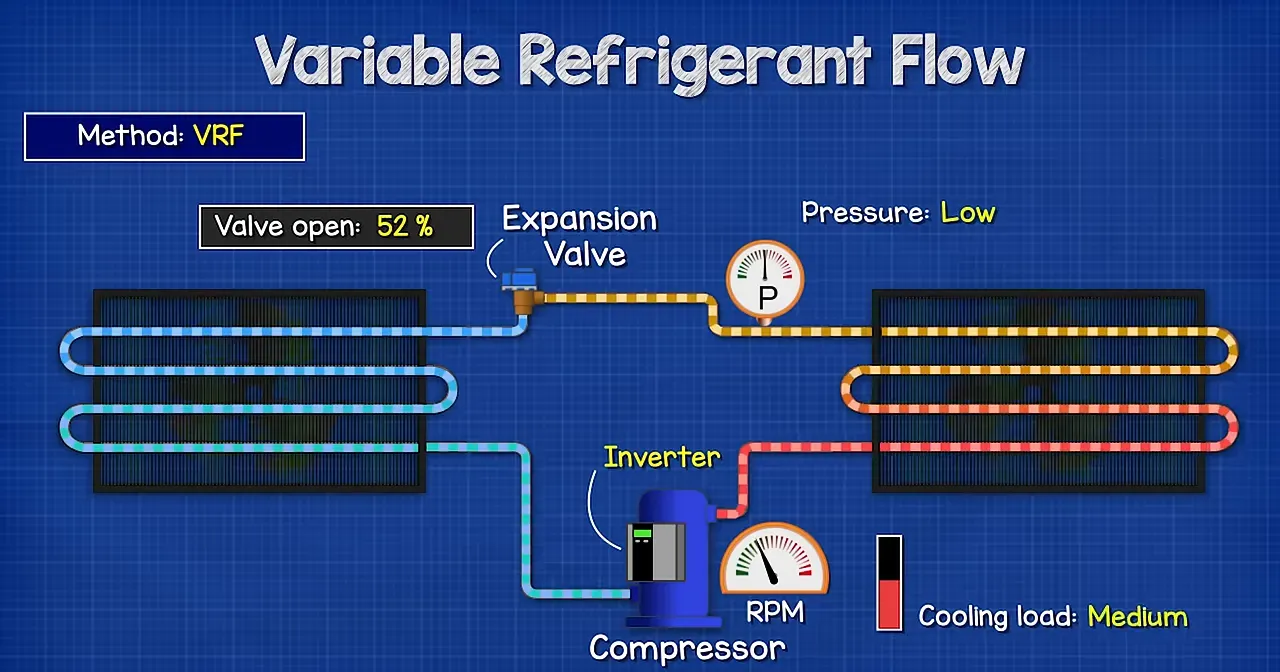

At the heart of any refrigeration-based HVAC system are four core components: the compressor, the condenser, the expansion device, and the evaporator. EMCO Utah’s technicians inspect and service each of these parts carefully when maintaining or repairing VRF equipment.

Compressor

The compressor pressurizes refrigerant and moves it through the system. In modern VRF systems, the compressor is inverter-driven, allowing continuous and variable speed operation. This modulation lets the compressor push only the refrigerant necessary for the current load, reducing energy consumption and providing smoother temperature control compared to simple on/off compressors.

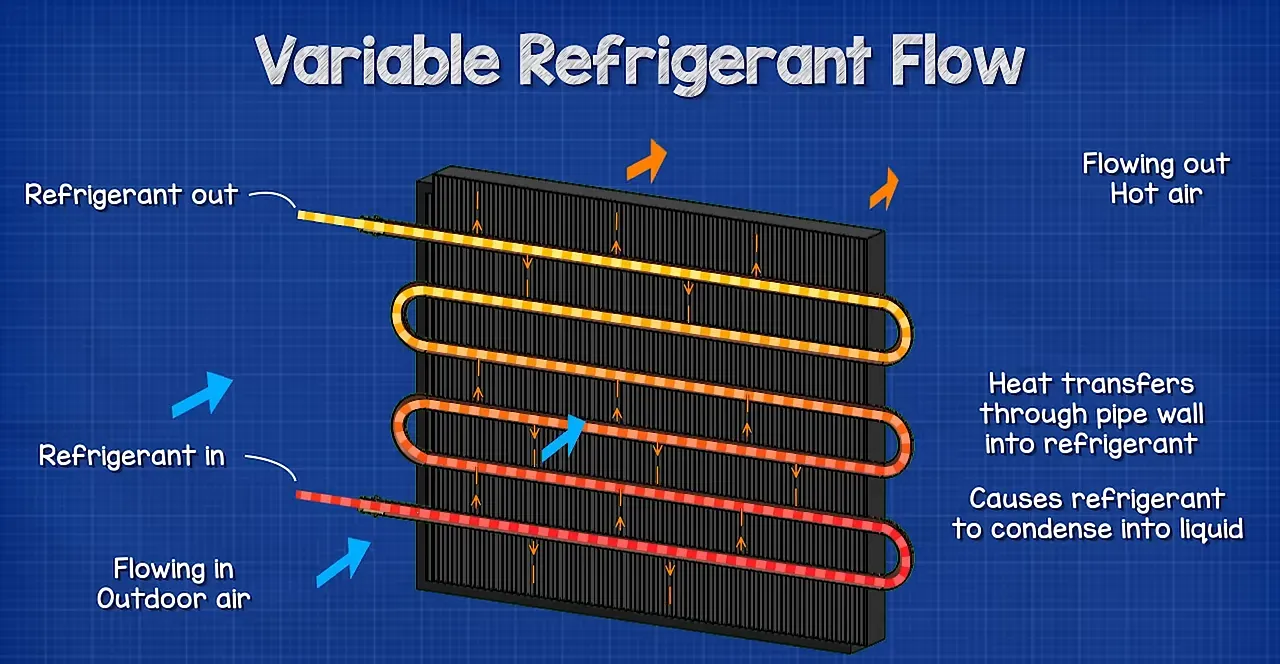

Condenser and Evaporator (Heat Exchangers)

Both the condenser and evaporator are heat exchangers that transfer thermal energy between refrigerant and air without direct contact. Depending on mode—cooling or heating—one acts as a condenser while the other acts as an evaporator. EMCO Utah technicians check fins, clean coils, verify fan operation, and confirm proper refrigerant flow through these exchangers.

Expansion Devices

Expansion devices convert high-pressure liquid refrigerant into a low-pressure mixed liquid-vapor stream before it enters the evaporator. VRF systems commonly use electronic expansion valves or thermostatic expansion valves that regulate superheat—the amount of additional heat added to ensure vapor is completely gaseous before the compressor suction.

EMCO Utah technicians calibrate expansion valves and monitor superheat values during service calls to optimize efficiency and prevent liquid return to the compressor, which can cause damage.

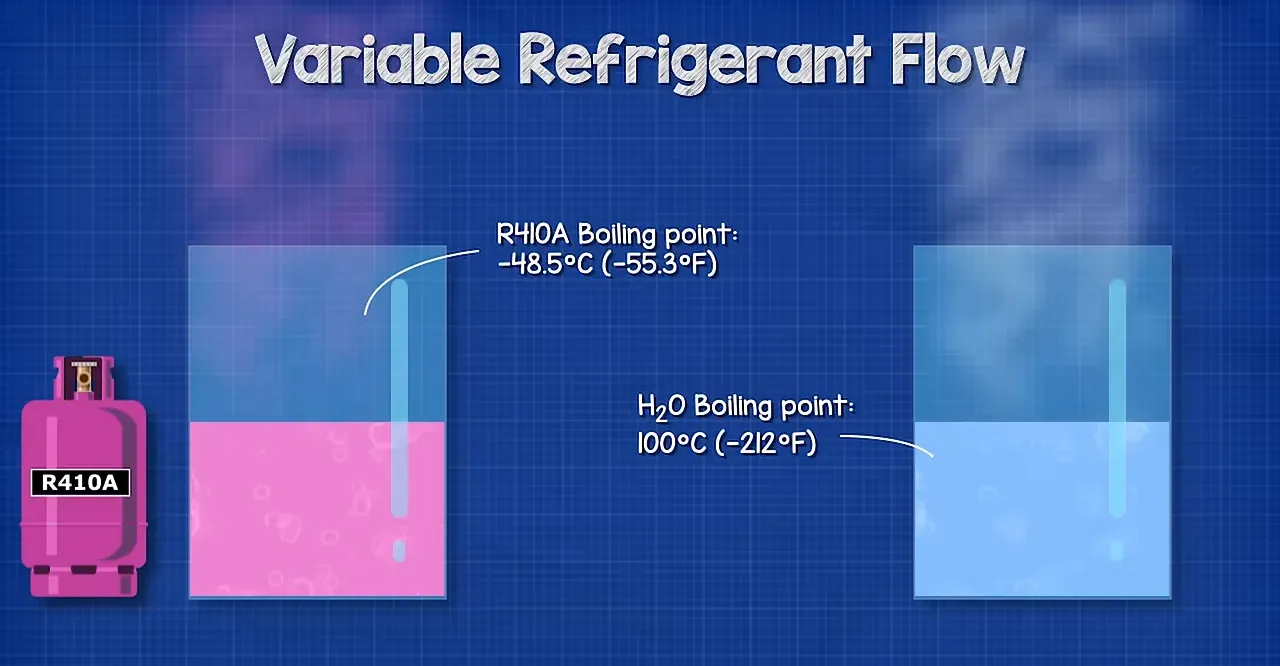

Refrigerant and Refrigerant Lines

Refrigerants in VRF systems have extremely low boiling points compared to water, allowing thermal energy to be absorbed from outdoor air even at low temperatures. EMCO Utah performs leak detection, pressure verification, and refrigerant charging as part of regular maintenance and repair operations. Modern systems may use R410A or other low-GWP refrigerants; technicians must follow charge and safety guidelines for each refrigerant type.

How VRF Systems Provide Both Heating and Cooling Simultaneously

One of the standout capabilities of VRF systems is heat recovery: the ability to provide heating to some zones while providing cooling to others at the same time. This is a major advantage in buildings with staggered occupancy or mixed uses—like a hotel where some rooms need cooling while a lobby or office space requires heating.

Basic Heat Pump Operation

When operating in heating mode, a VRF system runs as a heat pump, collecting thermal energy from the outdoor air (even when it is cold) and compressing the refrigerant to increase temperature and pressure so that heat can be delivered indoors. Thanks to refrigerants with very low boiling points (for example, typical modern refrigerants have boiling points far below zero Celsius), outdoor air still contains usable thermal energy in winter months. EMCO Utah ensures compressors and controls are optimized so this heat transfer remains efficient throughout seasonal changes.

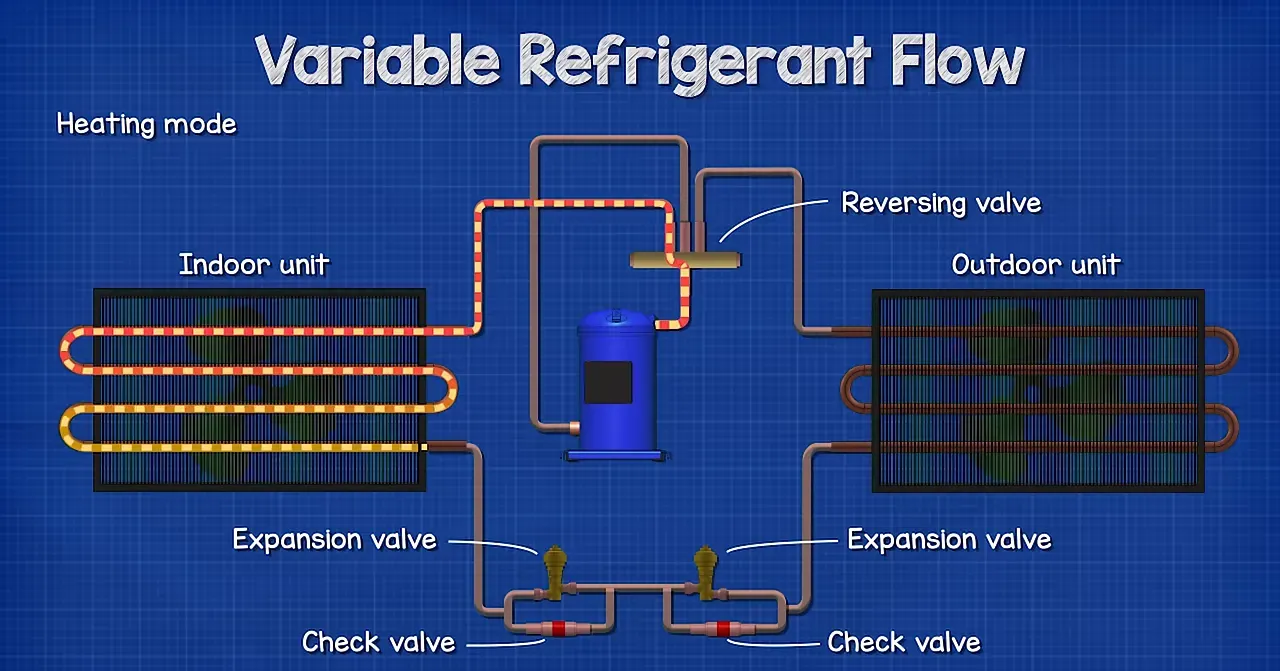

The Reversing Valve and Mode Switching

To switch between cooling and heating, VRF systems use a reversing valve. By sliding internal ports, the reversing valve routes the hot discharge from the compressor to either the outdoor or indoor heat exchanger depending on the chosen mode. Reversing-valve functionality is critical to mode selection and is a regular inspection item during EMCO Utah service visits.

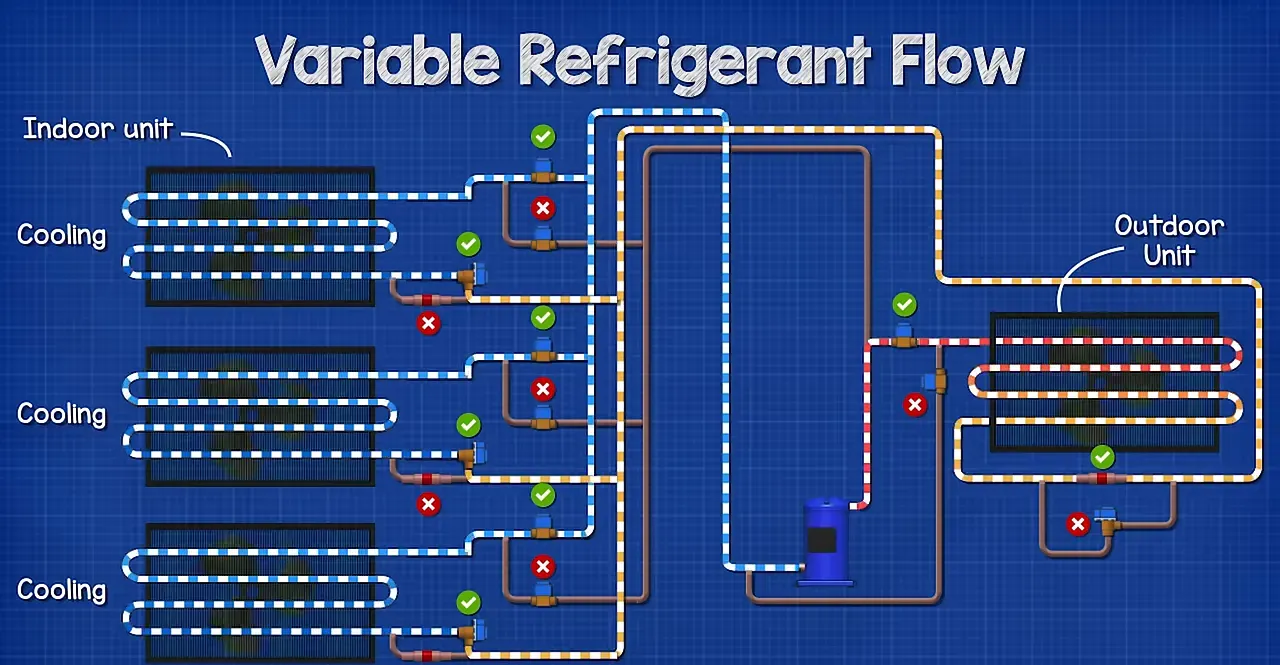

Heat Recovery with Branch Controllers

For systems that allow mixed-mode operation—some zones heating and some cooling—branch controllers (or branch selector units) are used. Each indoor unit connects to a branch controller containing a set of valves that direct liquid, suction, or hot gas lines to the indoor coil as required.

In a heat-recovery situation, hot refrigerant from zones requiring heating is routed to zones requiring cooling, transferring thermal energy directly without repeated outdoor rejection and absorption. EMCO Utah tests branch controller valves, checks piping integrity, and ensures the control logic is functioning so heat recovery remains reliable and efficient.

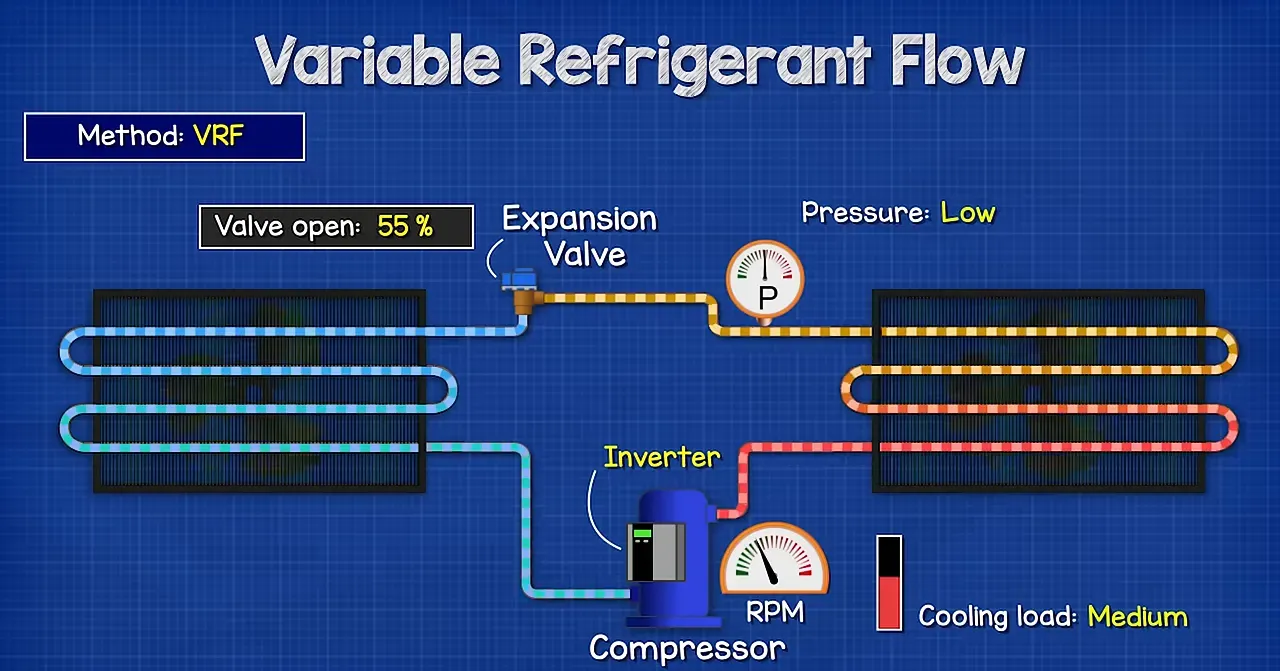

Inverter Technology: Matching Compressor Speed to Demand

Traditional compressors operate either fully on or completely off. VRF systems use inverter drives to modulate the compressor speed continuously. When indoor demand drops, expansion valves restrict flow; pressure rises and the inverter reduces compressor speed to match the decreased refrigerant requirement. This avoids inefficient unloading or frequent start-stop cycles, lowering energy use and reducing mechanical stress.

EMCO Utah inspects and verifies inverter performance during service calls. Symptoms of drive-related problems include unusual vibration, erratic temperature control, or abnormal current draws on startup. Diagnosing inverter faults often involves reading drive alarms, verifying DC bus voltages, and checking motor feedback devices.

Common VRF Faults and What EMCO Utah Does to Repair Them

Like any HVAC technology, VRF systems have common issues that require professional attention. EMCO Utah’s technicians are trained to address these specific faults efficiently and with minimal downtime.

- Refrigerant leaks: Leak detection, repair, and refrigerant recovery/charging. VRF piping runs connect multiple indoor units, so prompt leak location and repair prevent performance loss and environmental impact.

- Compressor failure or wear: Diagnosis of electrical issues, inverter faults, and mechanical failure. EMCO Utah can replace compressors or perform staged repairs to restore service quickly.

- Expansion valve and superheat mis-adjustment: Incorrect superheat causes poor performance and possible liquid return. Techs adjust or replace expansion devices and confirm superheat setpoints under live load conditions.

- Control and communication errors: Branch controller faults, sensor failures, and communication issues between indoor units and the outdoor inverter package. EMCO Utah performs system-level troubleshooting and controller replacement when necessary.

- Heat exchanger fouling: Dirty coils reduce capacity. Cleaning coils, checking fans, and restoring airflow are standard parts of service to recover efficiency.

- Electrical issues and protective devices: Failed contactors, tripped protective devices, or poor electrical connections can cause unit shutdown. EMCO Utah conducts thorough electrical inspections and corrective measures.

Maintenance Best Practices for Long-term VRF Performance

Proactive maintenance extends equipment life, reduces emergency repairs, and keeps energy costs in check. EMCO Utah recommends a service schedule tailored to commercial conditions in St. George:

- Biannual inspections: Before peak cooling season and before heating season, checking coils, filters, refrigerant levels, fans, and electrical components.

- Quarterly filter and airflow checks: Indoor units in high-occupancy zones may require more frequent filter changes to maintain indoor air quality and consistent airflow.

- Annual refrigerant and leak testing: Full pressure tests, dye or electronic leak detection, and corrective actions if any leaks are detected.

- Control system and sensor calibration: Verifying temperature sensors, thermostats, and branch controller logic to ensure accurate superheat control and coordinated operation.

- Inverter and motor inspections: Examining drive units, motor bearings, and electrical connections for wear or abnormal signatures.

- Training for on-site staff: Educating building operators on recommended setpoints, basic troubleshooting steps, and when to call for help.

EMCO Utah applies OEM-recommended maintenance practices and adjusts schedules to local environmental conditions—St. George’s hot, dusty summers and relatively mild winters—ensuring filters and coils are cleaned more often and refrigerant performance remains consistent.

Why Heat Recovery Matters to Building Owners in St. George

Heat recovery saves energy by transferring unwanted heat from cooling zones directly to heating zones. For mixed-use buildings—like hotels with warm guest rooms and cooler functional spaces—heat recovery reduces the need to run separate heating appliances or outdoor units, leading to lower operating costs and simplified maintenance.

EMCO Utah emphasizes heat-recovery system commissioning to ensure proper balancing. When loads are perfectly balanced (for example, two zones heating and two zones cooling with equal magnitude), outdoor units might not need to run at all; thermal energy circulates internally. When loads are unbalanced, EMCO Utah identifies the minimal set of outdoor units necessary to restore thermal balance, minimizing unnecessary energy use while maintaining comfort.

Retrofit and Upgrade Options

Existing commercial buildings can often be retrofitted with VRF systems to reduce footprint and improve zone control. EMCO Utah evaluates site conditions, examines existing ductwork and electrical service, and models expected savings versus cost. Common retrofit options include:

- Converting multiple rooftop units or packaged systems into a single VRF outdoor with multiple indoor heads for zoned control.

- Replacing aging chillers or boilers in parts of a building with VRF indoor units to provide fast-responsive zone conditioning.

- Adding branch controllers to support mixed-mode heat recovery where partial renovation allows piping upgrades.

- Upgrading controls and sensors to modern, networked interfaces for improved scheduling and fault detection.

EMCO Utah provides a site assessment to recommend the most cost-effective retrofit plan and explains the payback period based on local energy costs and typical occupancy patterns in St. George.

Local Considerations: St. George Climate and VRF Performance

St. George, Utah experiences hot summers and mild winters. VRF systems with inverter-driven compressors can deliver substantial energy savings in climates where cooling dominates seasonal energy use. Important local considerations include:

- Dust and airborne particulates: Increased filter and coil maintenance intervals to prevent reduced heat exchange and airflow.

- Peak cooling loads: Proper sizing and commissioning to avoid capacity shortfalls during the hottest days.

- Landscape and rooftop access: Thoughtful placement of outdoor units and piping runs to optimize serviceability and reduce refrigerant piping complexity.

- Water savings: VRF systems do not rely on evaporative cooling or large condenser water loops, reducing water demand in arid climates.

EMCO Utah customizes maintenance schedules and component selection for properties in the area to maximize uptime and efficiency while minimizing lifecycle costs.

Cost Factors and Typical Service Scopes

Service and repair costs vary depending on the issue, system size, accessibility, and part availability. EMCO Utah offers transparent cost estimates and scopes, typically including:

- Diagnostic fee covering system-level testing, controls checks, and initial corrective actions.

- Repair fees depending on parts (valves, sensors, expansion devices, compressors) and labor, with emergent repair prioritization.

- Planned maintenance contracts that reduce emergency repair frequency and often lower overall yearly costs.

For commercial properties, a service contract often includes scheduled visits, priority emergency response, and system report cards that identify trends like declining capacity or creeping refrigerant loss—allowing building owners to plan capital expenditure rather than incur unexpected breakdown costs.

Choosing the Right Service Partner

VRF systems require specialized knowledge beyond typical packaged HVAC service. When selecting a partner, EMCO Utah recommends checking for:

- Experience with VRF and heat recovery systems—particularly commissioning, branch controller diagnostics, and inverter drive troubleshooting.

- Knowledge of refrigerant types and proper charging procedures, including environmental compliance and leak repair strategies.

- Ability to provide preventive maintenance agreements and quick emergency response in the local area.

- Clear communication and transparent cost estimates for parts and labor.

EMCO Utah offers local expertise in St. George, serving commercial clients with service teams trained in these specialized VRF technologies and offering tailored maintenance plans to match building usage patterns.

Frequently Asked Questions (FAQ)

What is the main difference between VRF and a traditional split system?

VRF systems modulate refrigerant flow and typically use one outdoor inverter-driven compressor to serve multiple indoor units, providing individual zone control and heat recovery. Traditional split systems usually use a single indoor-outdoor pair and lack the same fine-grained zoning and heat-recovery capability.

How often should VRF systems be serviced?

EMCO Utah recommends at least two full inspections per year—before the cooling and heating seasons. High-use or dusty environments may need quarterly inspections for filters and coil cleaning. A service contract can help ensure consistent attention and reduce emergency failures.

Can VRF systems provide heating in cold weather?

Yes. VRF systems operate as heat pumps, extracting thermal energy from outside air even in cold conditions thanks to refrigerants with very low boiling points. Efficiency decreases at very low ambient temperatures, but modern systems remain effective in the range typical for St. George winters. EMCO Utah evaluates performance expectations and may recommend supplementary heat sources only when necessary.

Is simultaneous heating and cooling efficient?

Yes—if managed correctly. Heat recovery lets thermal energy be transferred between zones, reducing the need to reject and re-acquire heat via outdoor units. EMCO Utah ensures branch controllers and control logic are commissioned so mixed-mode operation genuinely reduces energy consumption rather than causing control conflicts.

How are refrigerant leaks handled?

EMCO Utah locates leaks using electronic detectors and pressure tests, repairs piping or components, evacuates and recovers refrigerant as necessary, and then performs a vacuum and recharge to factory-specified charge levels. Preventive maintenance reduces the risk of leaks and protects system efficiency.

What is the expected lifespan of a VRF system?

With proper maintenance, VRF systems can run effectively for 15–20 years. Longevity depends on operating conditions, maintenance rigor, and load cycles. EMCO Utah provides life-cycle assessments and replacement planning to help building owners make informed budgetary decisions.

Conclusion and Local Support

Variable Refrigerant Flow systems represent a modern, efficient approach to commercial heating and cooling—especially for buildings with varied and simultaneous thermal demands. Heat recovery, inverter-driven compressors, and precise expansion control deliver comfort while lowering energy use when systems are well designed and maintained.

For building owners in St. George, Utah, EMCO Utah provides targeted servicing, repair, and retrofit expertise for VRF systems. From commissioning to preventive maintenance, emergency repairs, and system upgrades, EMCO Utah helps keep VRF systems operating reliably and efficiently in the local climate.

To schedule service, request an assessment, or discuss a retrofit plan, contact EMCO Utah at 435-256-8483.

Regular care and specialized repair keep VRF systems performing as intended. With the right partner handling commissioning and maintenance, the benefits of precise zone control, energy savings, and heat recovery are fully realized—helping commercial properties in St. George remain comfortable, efficient, and cost-effective year-round.